Medical Device

Thanks to the collaboration with the Professor of Posturology at the Catholic University of Milan Benedetto Toso, and thanks to the constant research for the perfect balance between innovation and high quality standards, an important milestone has been reached today, for the most demanding: our corporate mission sees the birth of new categories of ergonomic supports deposited as a medical device at the Ministry of Health.

Quality and Sustainability

High-quality materials, attention to detail and respect for nature: the Ergogreen philosophy of quality and sustainability is based on these three pillars, with the aim of giving its customers excellent products, but also protecting the environment. This is why Ergogreen nets are made with beech plywood from FSC-certified forests with mandatory reforestation and with recyclable materials. Sustainability, however, also means attention to health: this is why Ergogreen networks respect your sleep thanks to the absence of electromagnetic fields, non-toxic materials and finishes and the use of only E1 category glues with low formaldehyde emission.

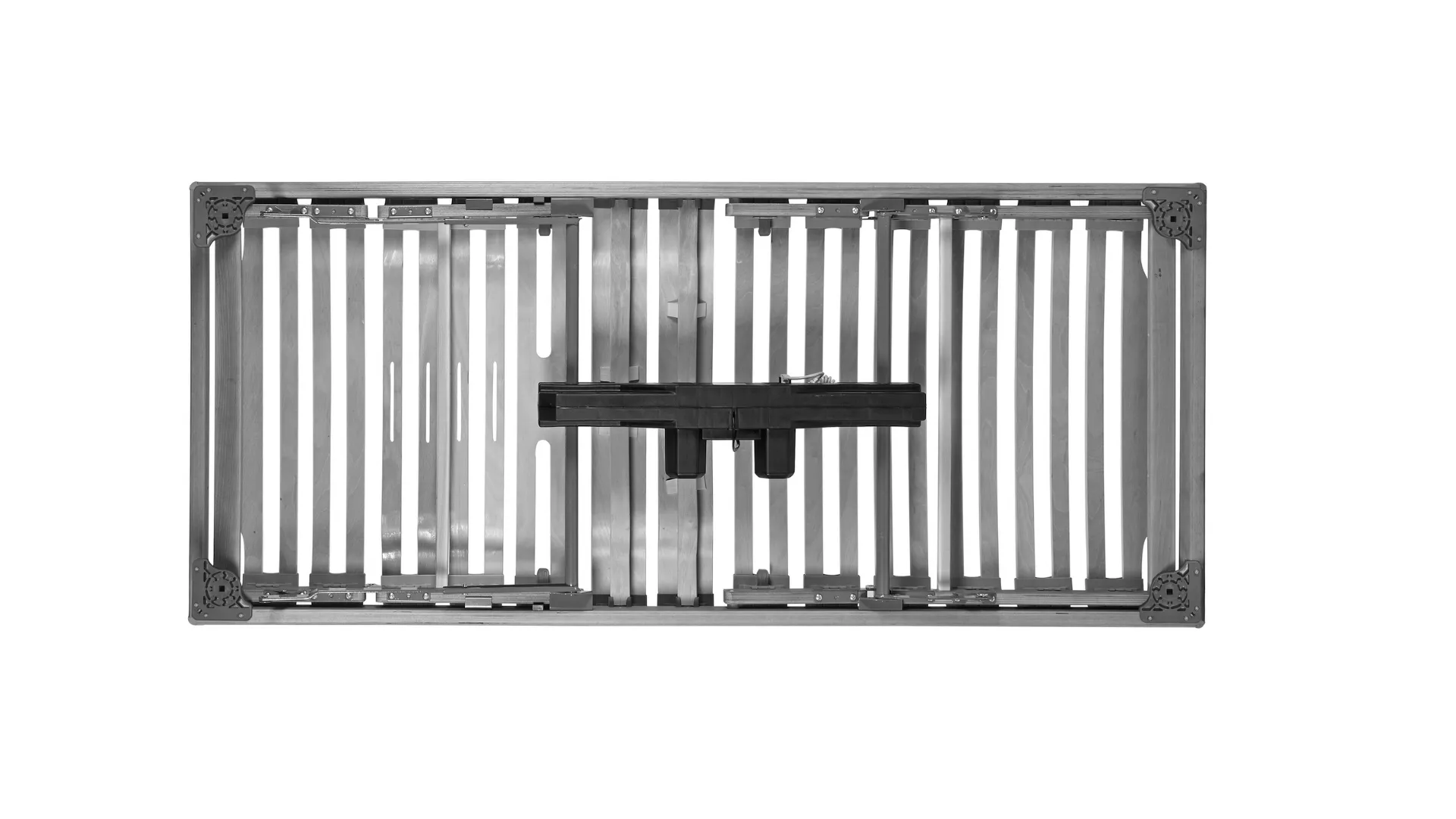

Solidity and Research

The structure of the Ergogreen nets is designed and built to last over time without deforming. To prove its high resistance are also Catas tests - renowned laboratory of tests and analyzes for the furniture wood sector - which simulate the use of the product over the years, for example with regard to fatigue, resistance to vertical shocks, stability, durability. , edge load and a number of crucial factors in a bed's life cycle. One of the most significant innovations brought by Ergogreen in the field of bed bases is the total absence of visible screws for the assembly of the structure and for movement.

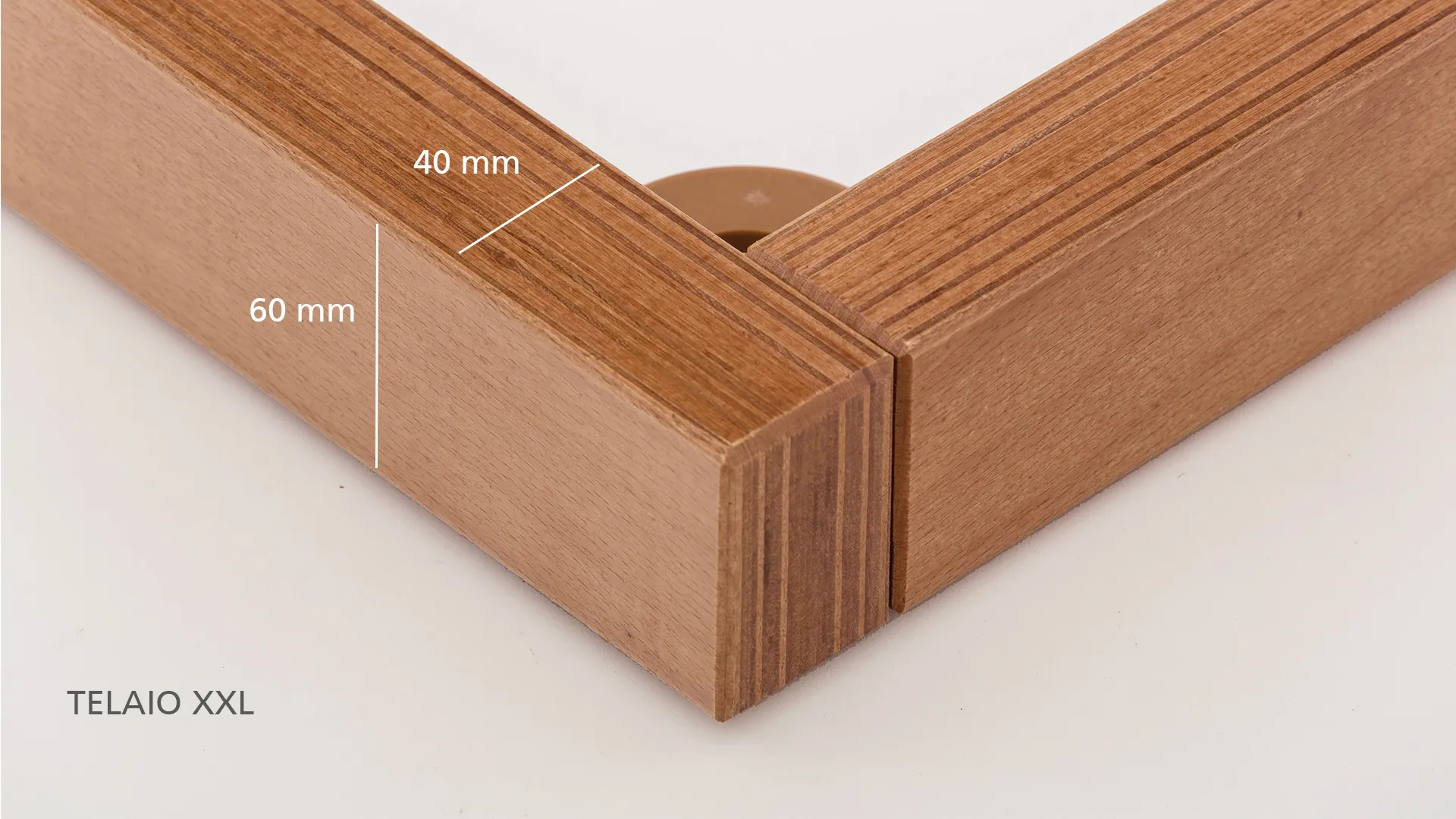

XXL bed bases

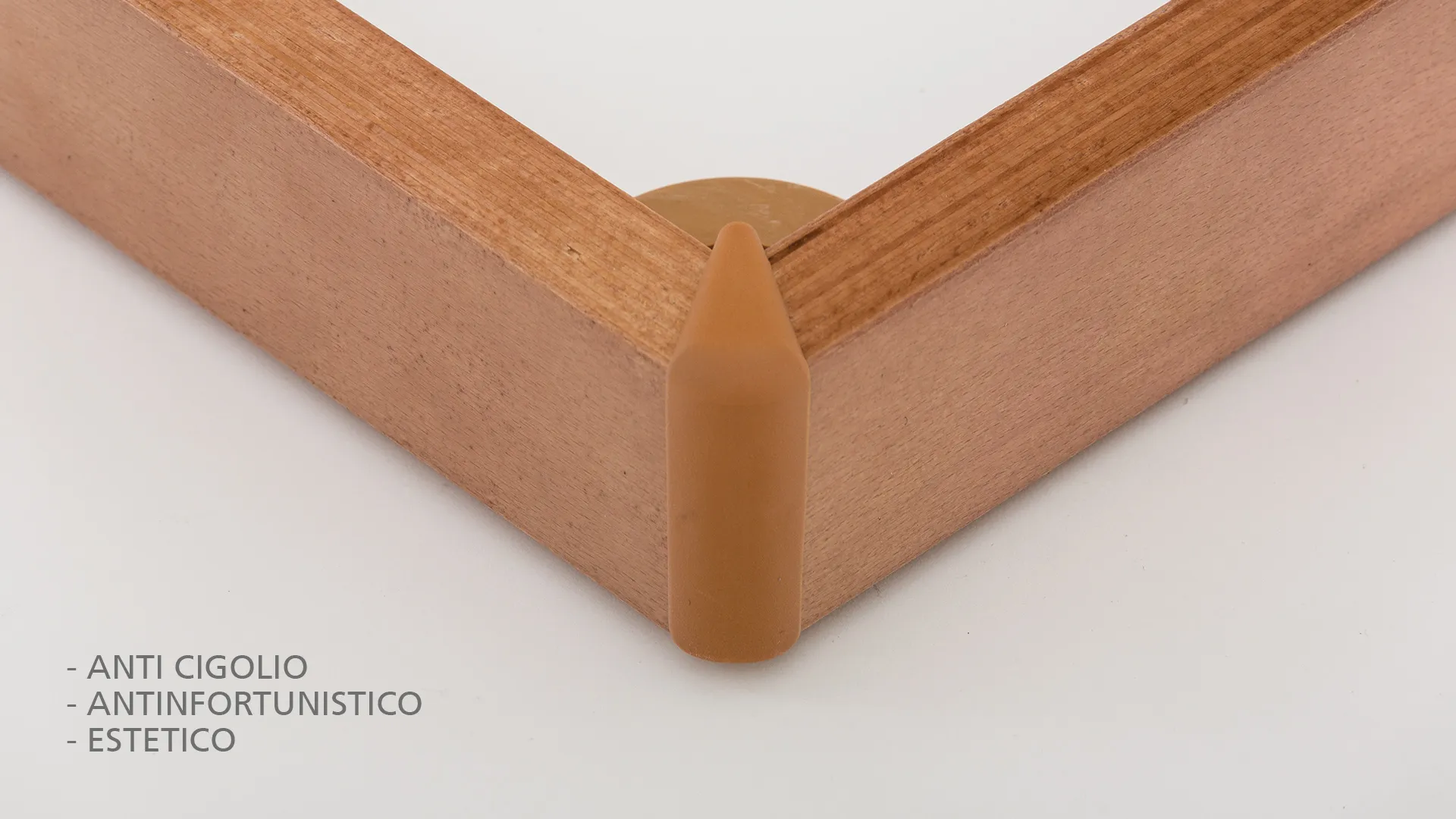

For those who have a body weight greater than 100 kg, the XXL version nets are also available, designed to guarantee the best rest and to withstand the greatest stresses without stress. For this reason the perimeter structure has an increased section of 60x40 mm., As well as the slats, with a thickness of 12 mm instead of 8 mm (+ 50%). In the XXL versions also the handling systems are suitably sized, with motors with 13000N thrust.

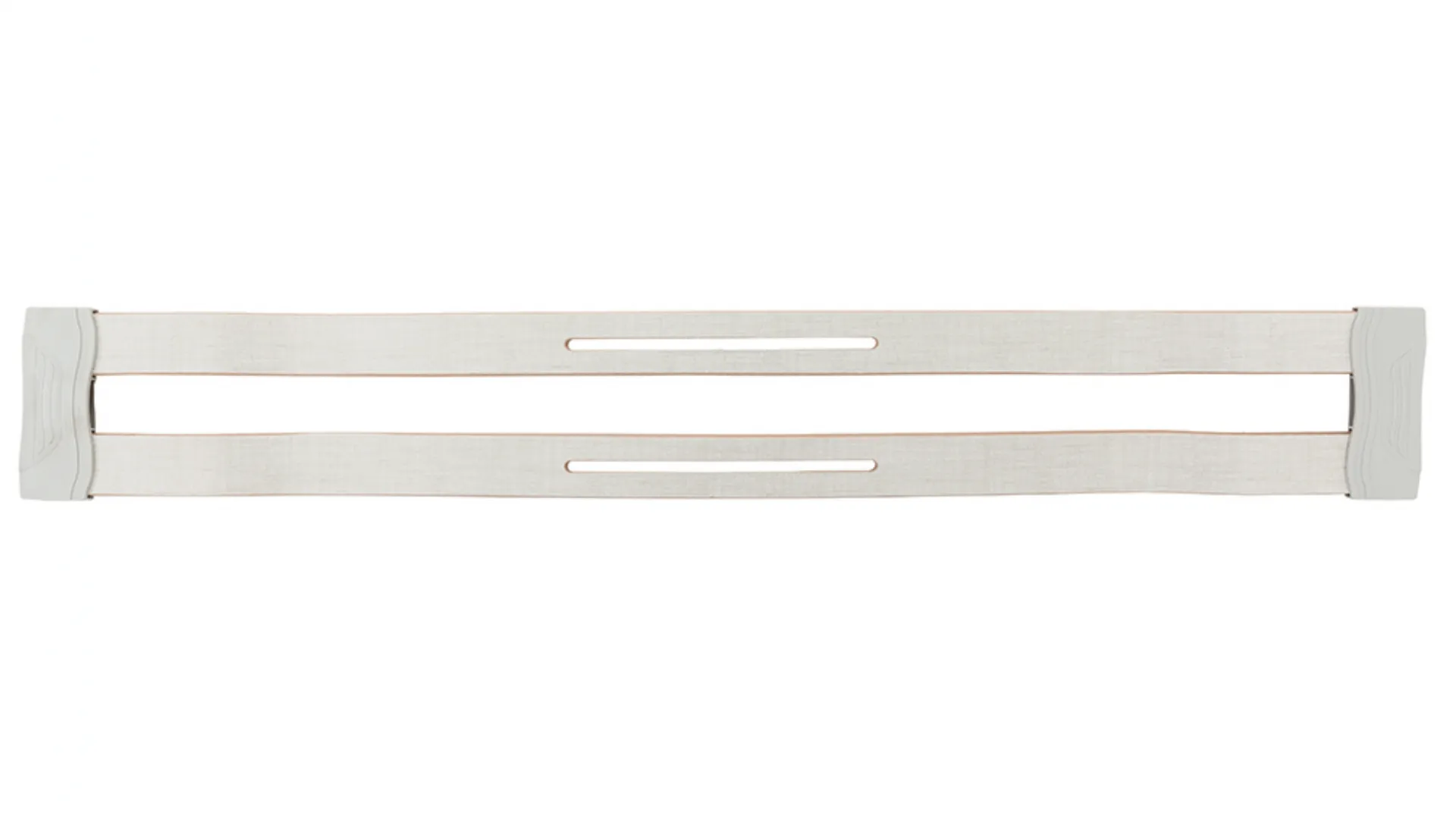

Exclusive finishings and slats

The different shapes, sizes and finishes of the slats that make up the Ergogreen bed bases guarantee ideal support and rigidity to every area of the body: so the rest is truly perfect. The slats covered in melamine film with a hygroscopic finish allow for a series of benefits both from the point of view of the duration of the structure and from the point of view of hygiene. The insulation of the surface of the slats from moisture resulting from the perspiration of the mattress allows them to maintain the correct curvature over time. The closure of the pores of the wood does not allow the stagnation of dust and mites, not to mention the ease of cleaning and sanitation. The protruding parts of the body (shoulder and pelvis) are welcomed by the gull-wing shape of the stave. The milling processes make the slats in the shoulder area more elastic while the rigidity adjusters allow you to adjust the flow rate in the pelvis area.

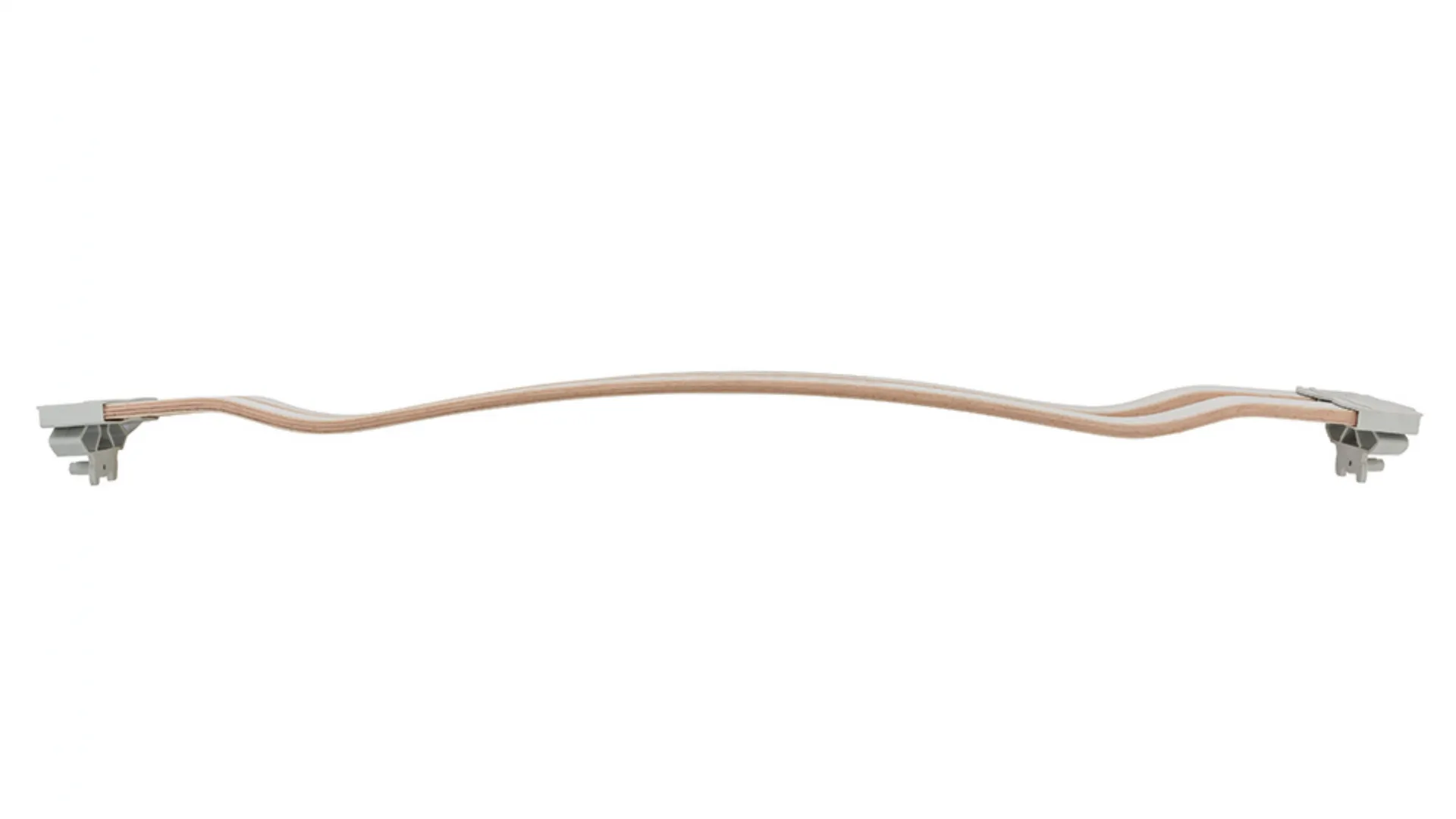

Mid-engine design

The handling of Ergogreen networks can count on high-performance, robust, silent and also ecological motors, since they are distinguished by their low energy consumption. The centrally positioned motor ensures balanced and parallel lifting of the backrest and footboard.